Star Trackers are high-precision optical attitude Trackers. However, they always have errors when leaving the factory. Engineers must correct these errors:

– Lens distortion

– Principal point offset

– Tiny focal length deviation

– Detector plane tilt and rotation

– Optical-to-structure misalignment (boresight error)

Without strict calibration, these errors cause star centroid errors. Then, star centroid errors directly lead to attitude errors. Finally, attitude errors can seriously affect critical missions. For example, they disrupt orbit maneuvers, satellite-to-ground communication, and Earth observation.

Calibration aims to push star Tracker accuracy to sub-arcsecond level (usually better than 1″). Modern high-resolution remote sensing satellites and deep-space probes demand this accuracy.

Calibration includes two stages: ground calibration and on-orbit calibration.

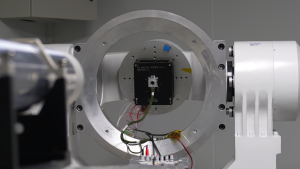

Engineers perform ground calibration in clean, dark laboratories. First, they build a high-precision initial parameter model. They mainly use these methods:

– High-precision turntable + single-star/multi-star simulator: A collimator generates infinite-distance starlight. Next, the turntable provides accurate angle references. Then, the system collects data at many attitudes and solves parameters.

– Thermal-vacuum calibration: Engineers place the Tracker in a thermal-vacuum chamber. This setup simulates space environment. They measure how temperature changes affect focal length and principal point. Finally, they build a thermo-optical model.

Ground calibration achieves very high accuracy. However, it cannot fully reproduce launch vibration, on-orbit thermal cycles, or radiation effects. Therefore, on-orbit calibration must complement it.

After the spacecraft reaches orbit, launch overload, thermal deformation, and outgassing pollution shift parameters. On-orbit calibration uses real star observations. It corrects the model in real time. Engineers usually run on-orbit calibration every few days or weeks. This process effectively suppresses performance degradation from thermal deformation and radiation damage.

– Least-squares batch estimation: The system collects hundreds to thousands of star images. Then, it solves all parameters at once.

– Recursive Kalman filtering: This method performs real-time online calibration. It requires little computation. Therefore, it suits on-board embedded processing.

– Distortion polynomial modeling: Engineers commonly use 5–10 order radial distortion plus tangential distortion. Some high-end Star Trackers also add thin-prism distortion terms.

– Boresight stability monitoring: Engineers statistically track boresight angle changes between multiple Star Trackers over long periods. This monitoring evaluates structural thermal stability.

Send us a message,we will answer your email shortly!