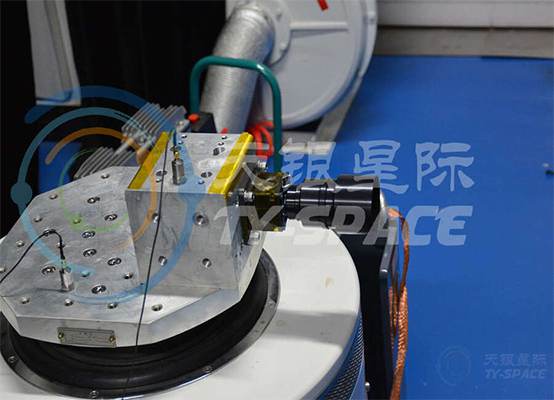

The frequency range of the electrical Shaker Tables is 5-3500Hz, the maximum no-load acceleration is 1000m / s2, and the maximum speed is 1.8m / s, the maximum displacement is 51mm, the maximum loadis 300kg, and the effective weight of the moving table is 6kg. Its working principle is the same as that of the loudspeaker, which is the current-carrying conductor is moved by the electromagnetic force in the magnetic field. When the current passing through the moving coil of the vibration table generates anexciting force with an alternating signal, a vibration movement occurs. The shaking table simulates the product vibration environment and is suitable for products working in a vibration environment such as national defense, aviation,and electronics. The tests include frequency sweep, sinusoidal vibration,random vibration, noise, and shock.

Programmable constant temperature and humidity test chamber temperature range is -60℃~+150℃, the volumeis 1000L. Constant temperature and humidity control system, PID control SSR, so that the heating and humidification of the system equals the amount of heat and humidity loss. The dry-wet bulb temperature measurement signal is compared with the A / D conversion input controller CPU and RAN and output to the I / Oboard. The I / O board sends instructions to make the air supply system and refrigeration system work and at the same time PID control SSR or heating SSR, or humidify SSR so that the amount of heat and humidity through the air supply system uniform test box to achieve a constant temperature and humidity. Applicable to the related industries such as optoelectronics, semiconductor industry, auto parts, household appliances, various electronic components and so on.

Vacuum degree can reach 5x10-5Pa, temperature range is -60℃~+120℃. During the simulation test, the test piece is in a working state, placed in the vacuum tank, and the gas in the container is extracted to the required value. The working parameters and environmental parameters of the test piece verify the adaptability of the test piece in a vacuum environment. The test is mostly used to inspect the manufacturing process of spacecraft equipmentand find that the spacecraft equipment fails early.